Exciting Features of Our Package

-

In Stock

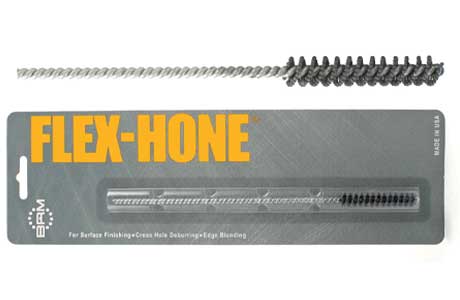

Brush Research Manufacturing (BRM) regularly stocks the Diamond Flex-Hone® tool in metric and inch sizes from 4mm to 1-1/2". Remember to order products by bore size.

-

Special Order

Contact Brush Research Manufacturing to discuss your application requirements, and to order diamond tools by bore sizes.

-

Abrasive

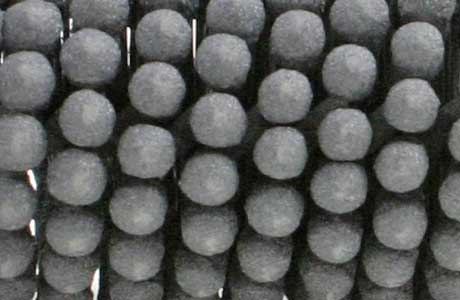

BRM's diamond honing tools are made with nickel-coated abrasive for greater heat dissipation and better bond retention. Resin-bonded diamond crystals provide high friability, which creates self-sharpening edges, too.

-

Mesh Sizes

The Diamond Flex-Hone® is available in three mesh sizes: 170/200, 800 and 2500. To determine which mesh size to select, consider the starting surface condition and the required surface finish.

-

Deburring

BRM's Diamond Flex-Hone® removes ridges of cut, torn, jagged, or folded metal that can cause part misalignments, affect dimensional tolerances, and limit the overall efficiency of machined components. Improve reliability and reduce the time spent on burr removal operations.

-

Edge Blending

BRM's diamond hones blend edges and eliminate stress risers that can reduce fatigue strength. Protect the quality of machined parts by producing smooth, radiused-edge transitions.

-

Surface Finishing

The Diamond Flex-Hone® is a low-temperature, abrading process that will remove mill and heat treat scale to expose the undisturbed base metal structure and produce a long-wearing surface. The tool also improves oil retention by creating a non-directional or cross-hatched pattern with valleys between the plateaus.

-

Improved Hole Quality

The Diamond Flex-Hone® removes micro-burrs left from drilling, reaming, and countersinking operations. Avoid improperly machined holes that can cause stress corrosion cracks and damage the structure of the metal.

-

Aerospace

The aerospace industry uses the Diamond Flex-Hone® to deburr, edge blend, and surface finish aircraft structures, helicopter rotor drive shafts, hydraulic control mechanisms, hydraulic swivel components, and other aerospace parts.

-

Defense

The military aircraft maintenance requires the use of the Diamond Flex-Hone from Brush Research to machine high-quality holes and avoid the loss of strength and temper in martensite, titanium alloys, and aluminum alloys.

-

Medical

The medical industry uses BRM's Diamond Flex-Hone® to finish medical parts that must the highest standards for quality and safety.

-

Bores, Bushings, Cylinders, and Wear Parts

Many manufacturers use flexible diamond hones from Brush Research to finish chromed and plated bores, guide and drill bushings, ceramic cylinders, electrical discharge machining (EDM) layers, and carbide wear parts.

-

Solve Difficult Finishing Problems

The Diamond Flex-Hone® from Brush Research Manufacturing can solve even the most difficult finishing problems. When a manufacturer of carbide wear rings needed to create a near-mirror surface finish, the Diamond Flex-Hone® was used in progressively finer grits.

-

Consistent Burr Removal and Radius

The design of BRM's flexible hones means that sharp, new abrasive rains constantly come into contact with the work surface, exposing fresh cutting particles. This provides consistent burr removal without producing an excessive radius.

-

Closer Part Contours

Flexible finishing tools conform to part contours in even the most demanding applications. For metal surfaces free of mill scale, even on the inside of helicopter rotor drive shafts, the Diamond Flex-Hone® delivers precise, consistent results.

-

Quality and Reliability

The Diamond Flex-Hone® refines the surface finish of holes and removes micro-burrs that can cause stress corrosion cracks.

The Diamond Flex-Hone® Advantage

- Hard materials

- Superior surface finishing

- Consistent deburring

- Reliable edge blending

- Close contours

- Self-sharpening

- Trusted for medical applications

- Ideal for aerospace components

- DOWNLOAD OUR 'FUTURE IN FINISHING WHITEPAPER' HERE